The northern company Flexiwaggon has signed an agreement to deliver a complete set of railway wagons with an option for an additional set (a total of 45-50 wagons) to the Austrian transport company CRD GmbH. Production of the wagons will take place in Luleå. Delivery of the first train set will take place in the third quarter of 2023.

Since its inception, the Austrian transport company CRD has been looking for more sustainable and flexible solutions for freight transport. Owner Christian Drosg has a well-established logistics company that transports bulk and package goods by trucks in Austria, Italy and the rest of central Europe.

"Our investment in Flexiwaggon's system means that we can now offer the Central European market flexible and sustainable door-to-door freight transport at a greatly reduced cost compared to other intermodal transports. Flexiwaggon's transport solution is fast, terminal-independent and cost-effective, while reducing fossil emissions significantly – something that is of great importance to our customers". Hans–Jürgen Stieber, Logistics Manager CRD GmbH.

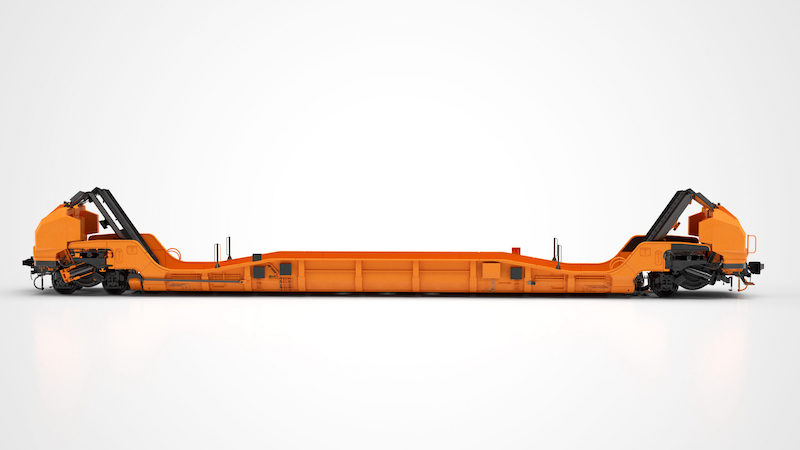

The agreement is a breakthrough for Flexiwaggon, which in recent years has worked very hard to further develop the trolley from previous prototypes. The new trolley is built for speeds up to 160 km/h. It generates its own electricity for, for example, charging electric vehicles and power supply of chillers and has a very flexible function for vehicles in crowded environments."It is of course extremely gratifying that with this agreement we see a breakthrough for Flexiwaggon in a European market. CRD GmbH has embraced Flexiwaggon's advantages, the agreement means that we get a stable partner for further expansion in Europe.Jan Eriksson, innovator and founder of Flexiwaggon.

The trolleys will be manufactured by GISAB (today part of Jernbro Services AB) with Swedish premium steel from SSAB. SSAB will also contribute with material and production optimization, GISAB has with its commitment been very involved in the breakthrough of green innovation."We are extremely pleased with the partnership with Flexiwaggon for the production of the trolley, full commissioning of Flexiwaggon means that we have good opportunities to expand the Jernbro Group's business in green transition and create new jobs here in" Norrbotten.Boris Lindberg, CEO GISAB.

"Within SSAB, we have several future projects that we see very positively from a sustainability perspective. Reducing CO2 emissions is something that must happen, delivering high-quality premium steel to the production of Flexiwaggon fits well with our investment in fossil-free steel" Roland Törngren, SSAB EMEA AB.

Flexiwaggon's unique rail car makes it possible to transport trucks by rail, which greatly reduces emissions and contributes to faster, safer transport at lower cost. Flexiwaggon AB (publ.) based in Jämtland has been developing the trolley since 2000, in September 2022 final tests of the trolley in a traffic environment will begin before the start of production.of the trolley in traffic environment before the start of production.